Tribupneu is an advanced concept in industrial pneumatics that combines tribology (the science of friction) with pneumatic systems to improve performance and efficiency. In simple terms, it focuses on controlling friction while optimizing airflow inside pneumatic systems. This smart interaction helps reduce energy loss, minimize wear, and deliver smoother mechanical motion.

Unlike traditional pneumatic systems that rely only on air pressure, Tribupneu technology looks at how friction affects efficiency and long-term reliability. Because of this, Tribupneu systems are increasingly discussed in industrial automation, manufacturing, and robotics where precision, durability, and energy-efficient pneumatic systems matter most.

Origin and Concept Behind Tribupneu

The term Tribupneu comes from two ideas working together. “Tribo” refers to friction and surface interaction, while “pneu” relates to air or pneumatic power. This concept emerged as engineers looked for better ways to improve pneumatic technology beyond basic air pressure.

By addressing friction inside moving components, Tribupneu systems aim to create smoother operation, lower energy use, and longer system life. Today, this approach supports the shift toward smart pneumatic systems and more efficient industrial automation.

Also read: What is Inomyalgia and How to Manage Chronic Muscle Pain

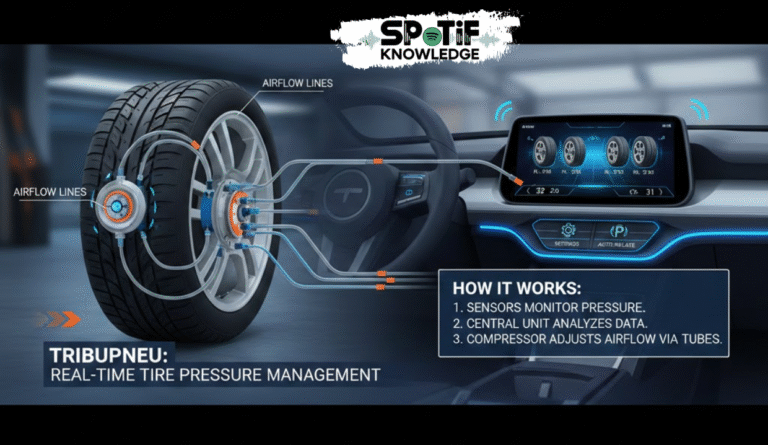

How Tribupneu Technology Works

Tribupneu technology works by balancing airflow and friction inside pneumatic systems. Instead of pushing air through components without control, it manages how surfaces interact during motion. This reduces resistance, improves pressure stability, and limits energy loss. Sensors and optimized materials often help regulate movement in real time.

As a result, Tribupneu systems deliver smoother operation, better efficiency, and improved reliability. This makes them ideal for industrial pneumatics, automation setups, and environments where consistent performance is critical.

Tribupneu vs Traditional Pneumatic Systems

| Feature | Traditional Pneumatic Systems | Tribupneu Systems |

|---|---|---|

| Friction Management | Minimal | Optimized |

| Energy Efficiency | Moderate | High |

| Maintenance | Frequent | Reduced |

| Pressure Stability | Standard | Improved |

| Lifespan | Average | Extended |

Traditional pneumatic systems rely mainly on air pressure to create motion, often ignoring the impact of friction. Tribupneu systems, however, actively manage friction and airflow together. This leads to higher efficiency, smoother movement, and reduced wear on components.

While conventional systems may waste energy over time, Tribupneu technology helps improve durability and lower maintenance needs. For modern industrial pneumatics, this makes Tribupneu a smarter and more energy-efficient alternative.

Key Benefits of Tribupneu Systems

| Benefit | Description |

|---|---|

| Energy Efficiency | Reduces energy loss and lowers operational costs |

| Reduced Maintenance | Less wear on components for longer life |

| Smoother Operation | Optimized friction and airflow for consistent performance |

| Improved Reliability | Stable pressure and predictable system behavior |

| Cost Savings | Long-term reduction in downtime and maintenance expenses |

Tribupneu systems offer several advantages for modern industrial automation. By controlling friction and airflow, they help improve energy efficiency and reduce power waste. This leads to lower operating costs and more stable performance. Components experience less wear, which means fewer breakdowns and reduced maintenance.

Tribupneu technology also supports smoother motion and better pressure control, making it ideal for energy-efficient pneumatic systems used in manufacturing and robotics.

Real-World Applications of Tribupneu

| Industry | Example Uses | Key Advantage |

|---|---|---|

| Manufacturing | Conveyor belts, assembly lines | Energy efficiency |

| Robotics | Robotic arms, precision machines | Smoother motion |

| Automation | Smart factories, automated systems | Consistent pressure |

| High-Precision Equipment | CNC machines, measurement devices | Reduced wear and friction |

Tribupneu systems are widely used in industrial automation and manufacturing where precision and efficiency matter. They improve the performance of robotics, conveyor systems, and high-speed machinery by reducing friction and optimizing airflow.

Factories benefit from lower energy consumption and longer-lasting equipment. In smart factories and automated production lines, Tribupneu technology ensures smoother operations, consistent pressure, and reliable output, making it an essential part of modern energy-efficient pneumatic systems and advanced industrial processes.

Challenges and Limitations of Tribupneu

While Tribupneu systems offer many advantages, they also come with some challenges. Implementing this advanced pneumatic technology can be more complex than traditional systems, requiring specialized knowledge and training.

Initial setup costs may be higher, and compatibility with older machinery can be limited. Additionally, maintenance may need careful monitoring to ensure optimal friction control. Despite these considerations, the benefits in energy efficiency, durability, and performance often outweigh the challenges in modern industrial automation environments.

Tribupneu and Industry 4.0

Tribupneu systems play a key role in Industry 4.0 by integrating with smart manufacturing technologies. Sensors and automated controls allow real-time monitoring of friction and airflow, improving efficiency and reducing energy waste.

This technology supports sustainable industrial systems by lowering maintenance needs and extending equipment life. In automation and robotics, Tribupneu ensures precise, reliable performance, making it an essential component of modern energy-efficient pneumatic systems and the future of smart factories.

Is Tribupneu Worth Adopting?

Adopting Tribupneu systems makes sense for industries focused on efficiency, reliability, and precision.

Companies with high-speed machinery, robotics, or automated production lines can benefit from reduced energy use, lower maintenance, and longer-lasting equipment. While initial setup may cost more than traditional pneumatic systems, the long-term savings and performance improvements often justify the investment. For manufacturers seeking energy-efficient pneumatic systems and smoother operations, Tribupneu technology offers a smart, future-ready solution.

Future of Tribupneu Technology

The future of Tribupneu technology looks promising as industries move toward smarter, more energy-efficient pneumatic systems. Advances in sensor integration, automation, and materials will make Tribupneu systems even more reliable and cost-effective.

As industrial automation expands, this technology is expected to play a key role in sustainable manufacturing and precision robotics. Companies adopting Tribupneu early can gain a competitive edge through improved efficiency, reduced maintenance, and longer-lasting equipment, shaping the next generation of pneumatic solutions.

FAQS: Tribupneu

What is Tribupneu?

Tribupneu is a system that combines tribology (friction control) with pneumatic technology to optimize airflow and reduce wear. It is designed for industrial automation, robotics, and manufacturing systems, providing smoother motion, higher efficiency, and longer equipment life compared to traditional pneumatic systems.

How does Tribupneu improve energy efficiency?

By managing both friction and airflow simultaneously, Tribupneu reduces resistance and energy loss in pneumatic systems. This results in lower power consumption, reduced operational costs, and more stable performance in high-speed or precision machinery.

Where is Tribupneu used?

Tribupneu systems are used in industrial automation, smart factories, robotics, and manufacturing lines where consistent pressure, precision, and reliability are critical. It’s particularly useful in high-speed or high-precision equipment that demands efficiency and reduced maintenance.

Is Tribupneu worth the investment?

Yes, especially for industries focused on long-term efficiency, reliability, and energy savings. While initial setup may be more complex than traditional systems, the benefits in reduced maintenance, smoother operation, and improved energy efficiency typically outweigh the costs.

What are the limitations of Tribupneu systems?

Tribupneu may require specialized knowledge to implement, higher initial costs, and careful integration with existing equipment. Compatibility with older pneumatic systems can be limited. However, the long-term gains in energy efficiency, durability, and performance make it a valuable investment for modern industrial environments.

Final Thoughts

Tribupneu technology is transforming industrial pneumatics by combining friction control with optimized airflow. Its benefits—energy efficiency, reduced maintenance, smoother operation, and longer equipment life—make it ideal for industrial automation, robotics, and smart factories.

While initial setup may require investment and expertise, the long-term gains are significant. Companies adopting Tribupneu systems can improve performance, cut costs, and stay ahead in modern manufacturing. This technology is a key step toward the future of energy-efficient pneumatic systems.