When it comes to making strong and durable parts for various applications, one process stands out: investment casting. This method, especially when using materials like stainless steel, allows for the production of components that can withstand the test of time.

Have you ever wondered how products like car parts, medical devices, and kitchen utensils are made so accurately? The answer lies in investment casting. It not only offers excellent corrosion resistance but also provides the precision needed in today’s manufacturing world.

What is Investment Casting?

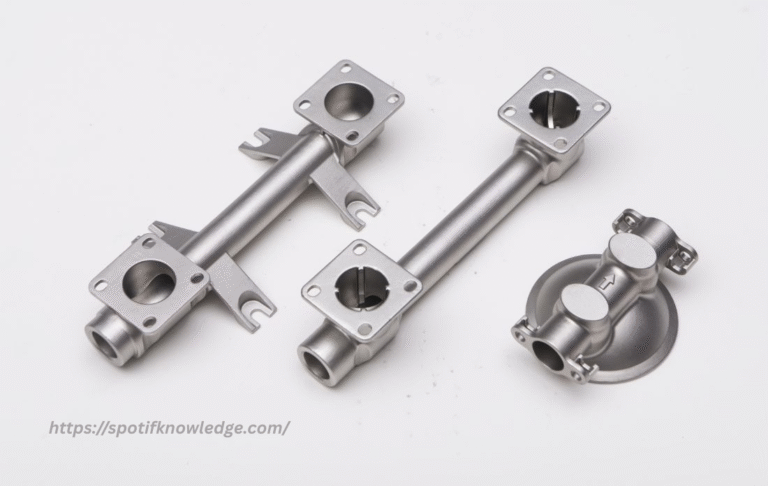

Investment casting, often referred to as lost-wax casting, is a manufacturing process where a wax pattern is coated with a ceramic shell. Once the shell hardens, the wax is melted away, leaving a hollow mold.

This allows molten stainless steel to be poured into the mold, creating detailed and complex shapes. This method is favored in many industries because it produces high-quality parts with great detail.

The Benefits of Stainless Steel in Investment Casting

Using stainless steel in investment casting brings several advantages. Here are some key benefits of using this durable material:

Corrosion Resistance

Stainless steel resists corrosion, making it ideal for parts in tough environments. This includes chemical plants, coastal areas, and places with extreme weather. This means that parts made from stainless steel can withstand exposure to saltwater, acid, and other corrosive substances without rusting or deteriorating.

High Strength

Stainless steel is very strong. It can handle heavy loads and high pressures. This makes it perfect for parts that support weight or face intense forces.

Precision

The investment casting process produces parts with highly accurate dimensions. This accuracy is vital for components that need to fit together precisely. Such precision is especially important in fields like aerospace engineering, where even minor deviations in part dimensions can lead to serious consequences.

With these advantages, it’s easy to see why industries like aerospace, automotive, and medical depend on stainless steel investment casting.

Applications of Investment Casting

Investment casting finds its way into various industries due to its versatility. Here are some common applications:

- Aerospace

- Automotive

- Medical Devices

All of these applications benefit from the superior qualities of stainless steel, combined with the precision of investment casting.

Choosing the Right Foundry for Your Needs

Finding a qualified foundry is critical for anyone looking to create components through investment casting. A reputable stainless steel investment casting foundry in Texas will have experience and the necessary technology to produce high-quality, precise parts. When selecting a foundry, consider the following factors:

- Experience

- Technology

- Customer Support

Choosing the right foundry can significantly impact the quality of the final product.

Why Investment Casting Matters

In summary, investment casting using stainless steel provides a reliable method for producing durable and precise components. Its benefits, including corrosion resistance and strength, make it a top choice across many industries.

Whether you need parts for aerospace, automotive, or medical applications, investing in high-quality components is crucial. Remember to choose a trusted foundry, like a stainless steel investment casting foundry in Texas, to ensure you receive the best results. Also Read

Start exploring the possibilities of investment casting today!